WORKFLOW

The complete production

process of P-501,

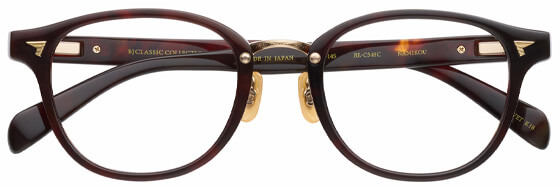

the masterpiece of the BJ CLASSIC COLLECTION

1st part

BJ CLASSIC COLLECTION started in the early 2000s.

P-501, one of the most famous models of the lineup,

harbors its soul through four-month-long production period.

Here we will introduce the complete process of P-501,

which starts from a piece of celluloid.

Cut The Celluloid Plate

Everything starts

from a single celluloid plate.

We refuse to compromise on the quality of our celluloid frames.

Our celluloid frames, which boast strong shape retention, beautiful polish, and a perfect f it, are beyond comparison.

Yet, since there is a risk to catch f ire at temperatures exceeding 170ºC, they cannot be machine-manufactured and must be hand-made by skilled craftsmen.

Our craftsmen carefully choose the thickness of each frame using their experience and expertise, so that our frames' thickness varies even within the same model depending on the model's color and other conditions.

Bend The Celluloid Plate

Our craftsmen's experiences

determine the shape.

We slightly bend the celluloid plate after cutting it out.

We dip the plate into our special highly heated oil to pressurize it, and then cool it down immediately.

The decisions of when and how are left in the hands of our craftsmen who have amassed an abundance of skill throughout their many years of experience.

Punch Out The Lens Holes

The lens holes

are punched out by hand

Since this phase of punching out the lens holes has a risk of fire, this process also cannot be mechanized.

Our hands-on craftsmanship remains a necessity.

Our craftsmen punch out the lens holes from bended celluloid plates one-by-one, and then dig V-shape ditches for the lenses.

Punch Out Frames

The basic shape

of P-501 emerges.

After punching out the holes for the lenses, we then punch out the frames.

What started as a simple celluloid plate, has now transformed into P-501’s basic shape.

Place The Nose Pads

Each model provides

different comfort.

It is not possible that all of our nose pads will be placed in the same position, because the best position varies depending on each model.

First, we place the basic molds of the nose pads and then leave them for a few days.

After they are applied to the frames completely, our craftsmen manipulate them by hand according to the shape of the model.

This process will define the first impression of comfort of our products.

Scrub The Frame

Our craftsmen bring

the frames to life

This is the highlight of the manufacturing process of celluloid frames. Our craftsmen rasp the cut-out fronts one-by-one.

Utilizing their experiences, passions, and intuitions, they make the detailed nuances such as f luent curves and sharp, yet soft, edges that are impossible to bring out by machines. This is the moment that our products’ shapes and subtleties can be seen.

Like frames, the temples will be rasped by hand, as well.It is safe to say that there are almost no brands that rasp temples, other than BJ.

This unseen additional process brings a smooth fit and touch.

Ara-Gara, The First "Gara"

We put front frames and temples

in our special rotary drum to polish.

We put abrasive compounds and chips to our special rotary drum called "Gara", and then insert the frames and temples, separately.

The composition of abrasive compounds and chips are top-secret and classified, but we change the composition depending on the temperature and the season.