The challenge of

crafting celluloid eyewear

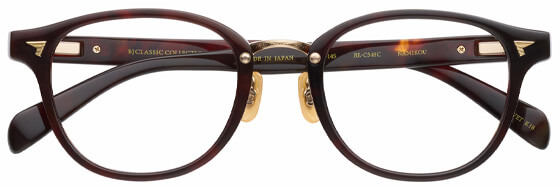

BJ CLASSIC COLLECTION deliberately revisits the challenging material “CELLULOID” to express its commitment to craftsmanship as its 20th anniversary.

Celluloid is one of the most suitable materials for eyewear. It is hard, elastic, and resistant to deformation or distortion. Its beautiful luster is a defining feature, and the more it is polished, the smoother it becomes, resulting in eyewear that feel comfortable against the skin.

In the meantime, celluloid is difficult to process due to its hardness, and with a low ignition temperature of 170°C, machine manufacturing is not almost capable. Thus, most of the production processes are done by hand, requiring the craftsmanship and expertise of skilled artisans. Today, even in Sabae, only a limited number of craftsmen can manage celluloid, making its production volume extremely low.

BJ CLASSIC COLLECTION will continue to take on the challenge of crafting celluloid eyewear, a pursuit that has been embraced since the foundation. With dedication and craftsmanship, BJ CLASSIC COLLECTION will work alongside artisans to uphold the tradition and pass it on to future generations.

WORKFLOW

Celluloid Plate

Celluloid is a synthetic resin made by mixing nitrocellulose and camphor.

It is characterized by its hardness and elasticity, making it resistant to deformation or distortion.

Initially matte, it develops its signature beautiful luster through repeated polishing.

Cutting

Each celluloid plate is carefully cut to shape the front frame.

Due to the risk of ignition, full automation is not possible.

Rough Shaping

Craftsmen file cut-out front frames by hand, one by one.

Using their experience and intuition, craftsmen create subtle details that cannot be achieved by machines.

Mud Buff Polishing

Polishing with fine-quality mud brings out the hidden luster within the celluloid.

Gloss Polishing

The final step to achieve a beautiful luster.

Every single part is polished with a gloss buff, further enhancing the luster of celluloid.

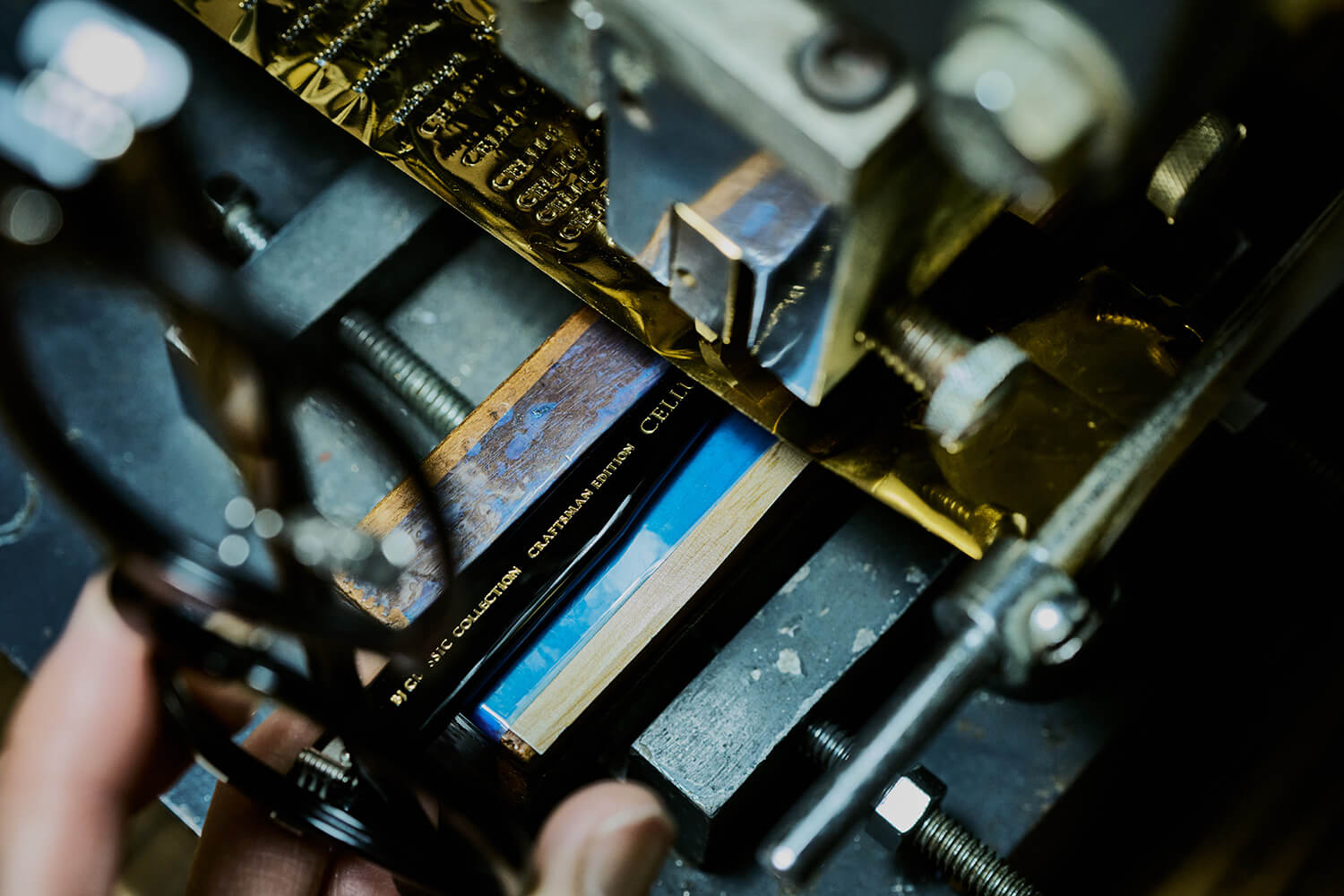

Stamping

After all processes are completed, the name engraving is the final step.

Only pieces that meet BJ’s proud standards receive this engraving.